Below procedures to be performed after it has been verified that the tractor/power unit has air released to the trailer and that the wet kit is producing 25-30 GPM at minimum of 2500 psi to the trailer.

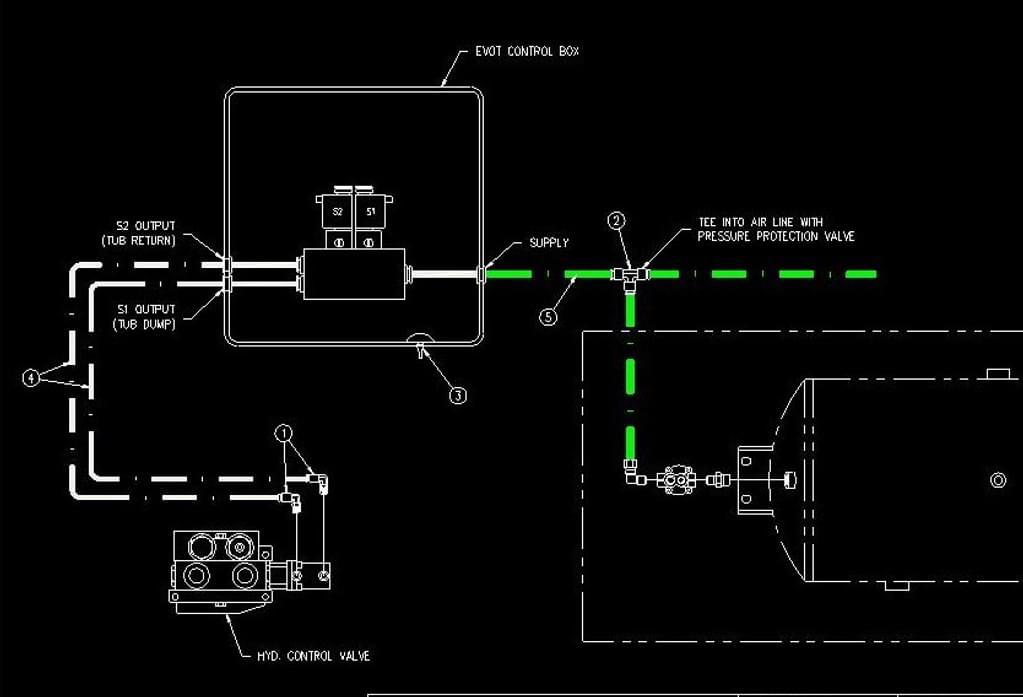

If air has been released to trailer, check to be sure that air is being supplied to the control box mounted toward front of trailer. If there is no air supply to the box, remove the pressure protection valve by the air tank and re-test. If there is now air, replace pressure protection valve.

Once air is verified, check for power to terminals that solenoid is attached to. If no power to terminals, check power source for proper wiring. If source checks ok, check wiring at back of socket to be sure there is no short. 6-pin trailer wiring shown in example.

If power at terminals is present, double check to be sure ground is intact.

Optional steps for trailer with tarp system lockout – Be sure that the tarp lockout proximity sensor is in proper position and that tarp is fully opened. This allows electrical signal to get to the solenoids. If switch is in active position and no power to solenoids, the proximity sensor may need replacement. Depending on lockout system you may be able to bypass the sensor via switch in box.

If verified there is power and air to each coil/solenoid, remove air lines from the hydraulic valve (see figure 1) and operate solenoids via switch in cab, to be sure that air is being supplied through each line to the hydraulic valve's air shifter. If no air to the valve then the coil/solenoid is bad.

If there is air supply to both lines to the hydraulic valve then the air & electrical portion of the system are working properly. Next step is to check the hydraulic portion of system.

If trailer seems to attempt to dump, goes up a few inches and stops, it is likely that the hydraulic pressure from the truck is going into the wrong line/coupler. Double check to be sure that pressure line into the trailer is connected to the outermost (most roadside) connection on the trailer frame.

Sometimes the air shift on the hydraulic valve will stick, or could have come loose from the spool in the valve. If connection between air shift and spool is solid, loosen the screws holding the air shift on, move the shifter a bit, then re-tighten the shifter. Put some tool oil in the air inlets and retry to shift the valve.

If still not working, you can remove the cap on the opposite side of the hydraulic valve from the air shift. Removing the cap will expose the spool and allow you to check for movement in the spool. If it moves, re-try to activate via electric switch in cab. If trailer still will not dump, replacement of the hydraulic valve may be necessary.

**Trailer dumps when empty, but not under load means that the trailer is not getting high enough pressure on the hydraulic flow from the power unit.**

Source: https://sidedump.com/support/guides/trailer-wont-dump-troubleshooting

Posted by: youngsionuirt58aep.blogspot.com